Welcome

ENTERPRISE INTRODUCTION

Jiangsu Leap Machine Co., Ltd. was established in 1994, with 50,000 square meters. We are a private enterprise specializing in precision forgings and machined components. We also handle mold manufacturing and parts machining in house.

We are located in Jiangsu Province, a central hub of the delta economy region, about 200 km from Shanghai Port with convenient transportation and logistics.

To meet development needs, Jiangsu Leap established Changzhou Leap Forging Co., Ltd. in 2013, with the two plants located 7 km apart. Changzhou Leap Forging Co. has 22,000 square meters, with workshops adopting green energy. Our professional team comprises over 160 engineers, technicians and employees with strong mold design/production capabilities and product development/manufacturing potential.

Leap Machine and Leap Forging always put customer needs as top priority. We've established an integrated, streamlined industrial chain containing mold design/production, forging, heat treatment, machining and inspection processes.

Experienced Employees And Management

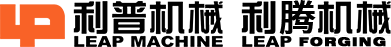

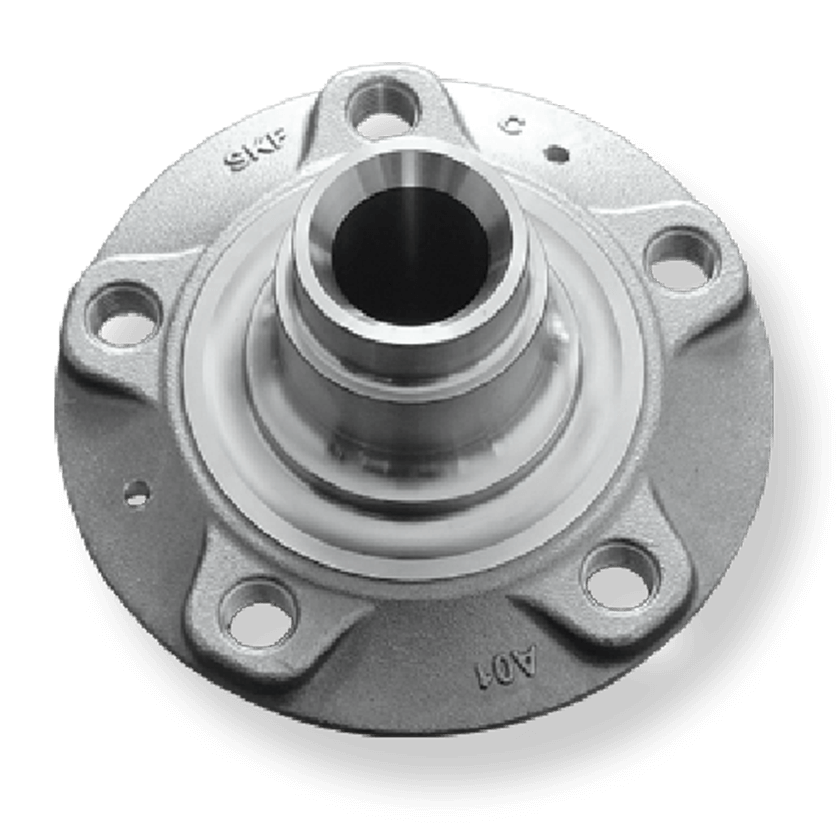

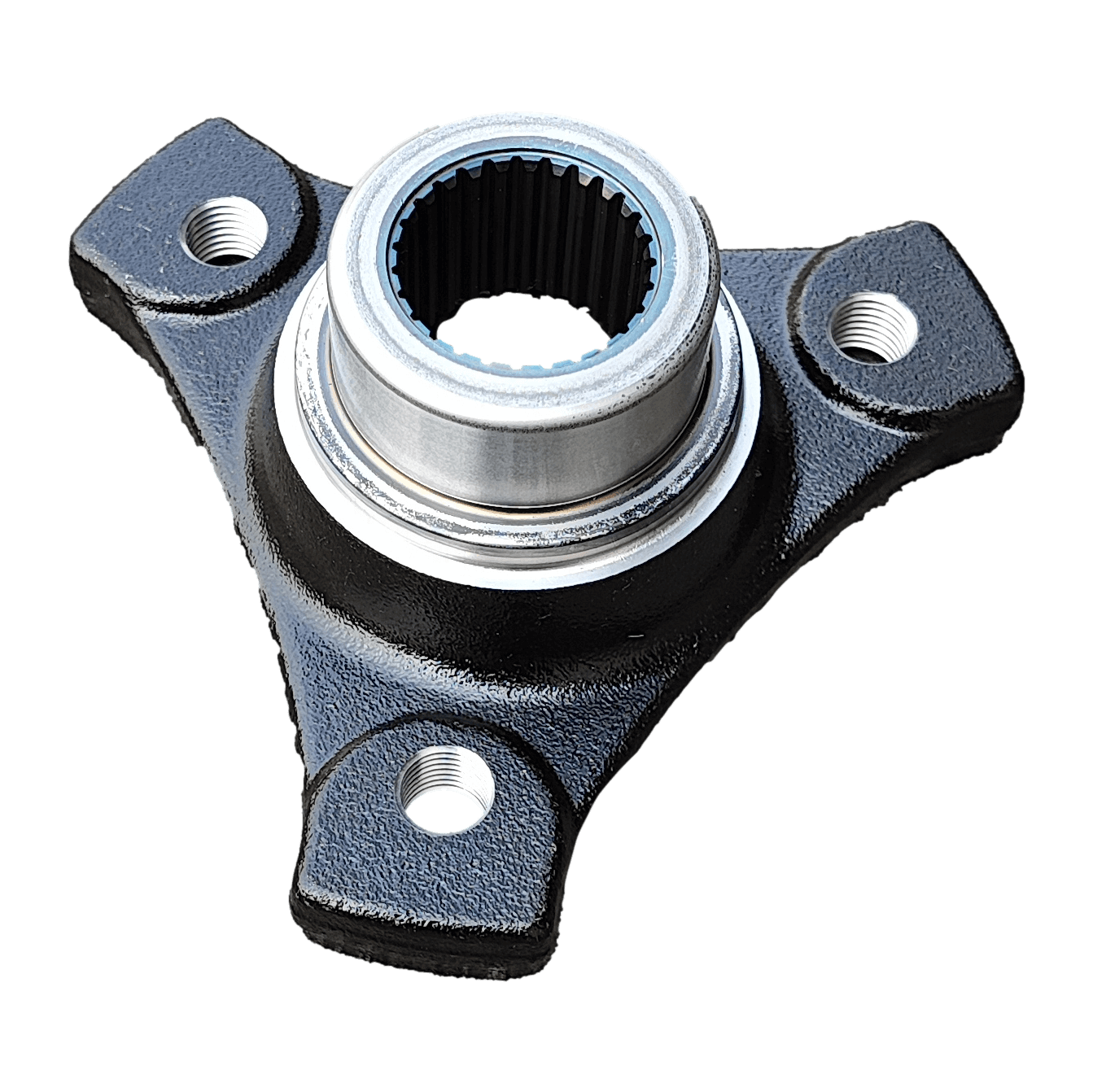

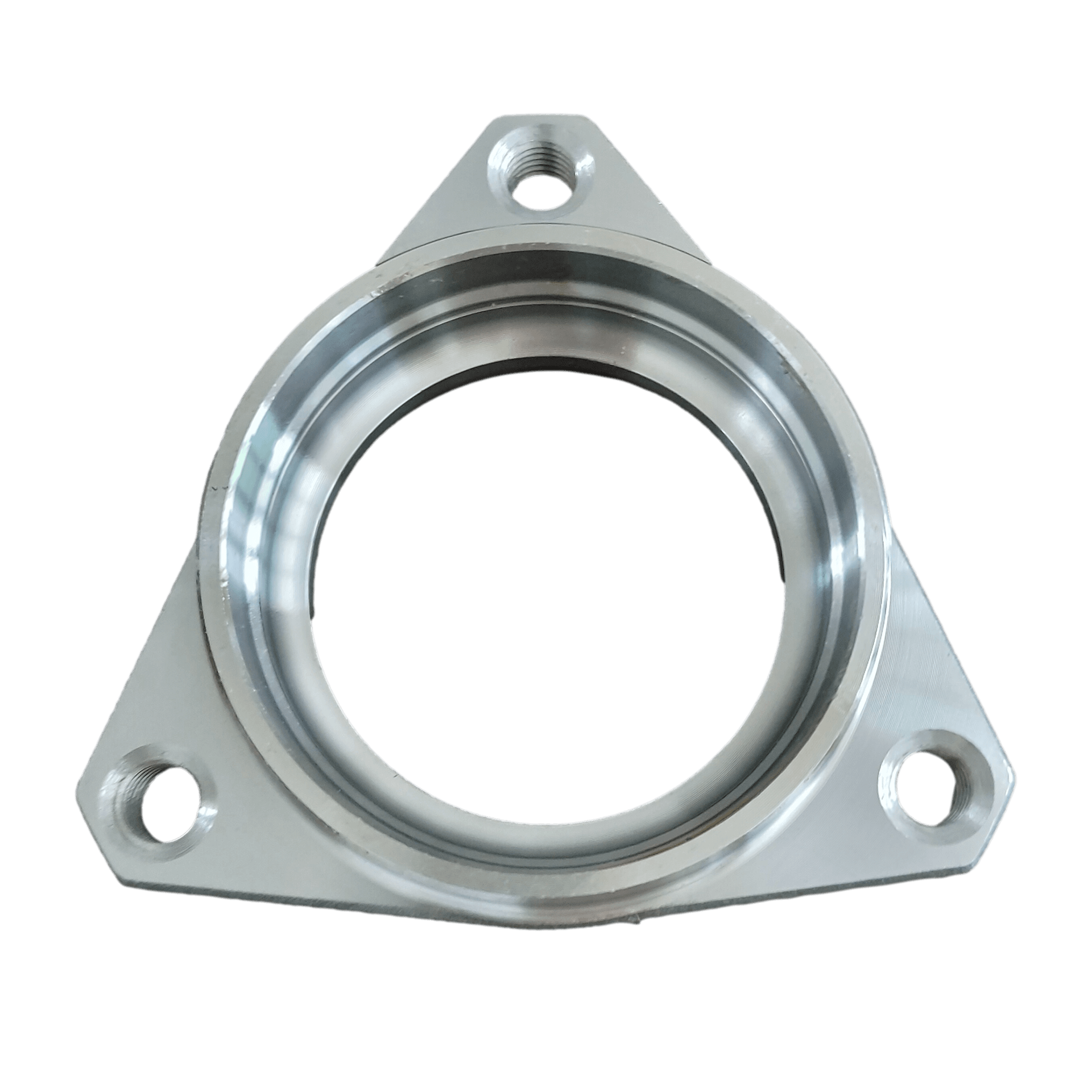

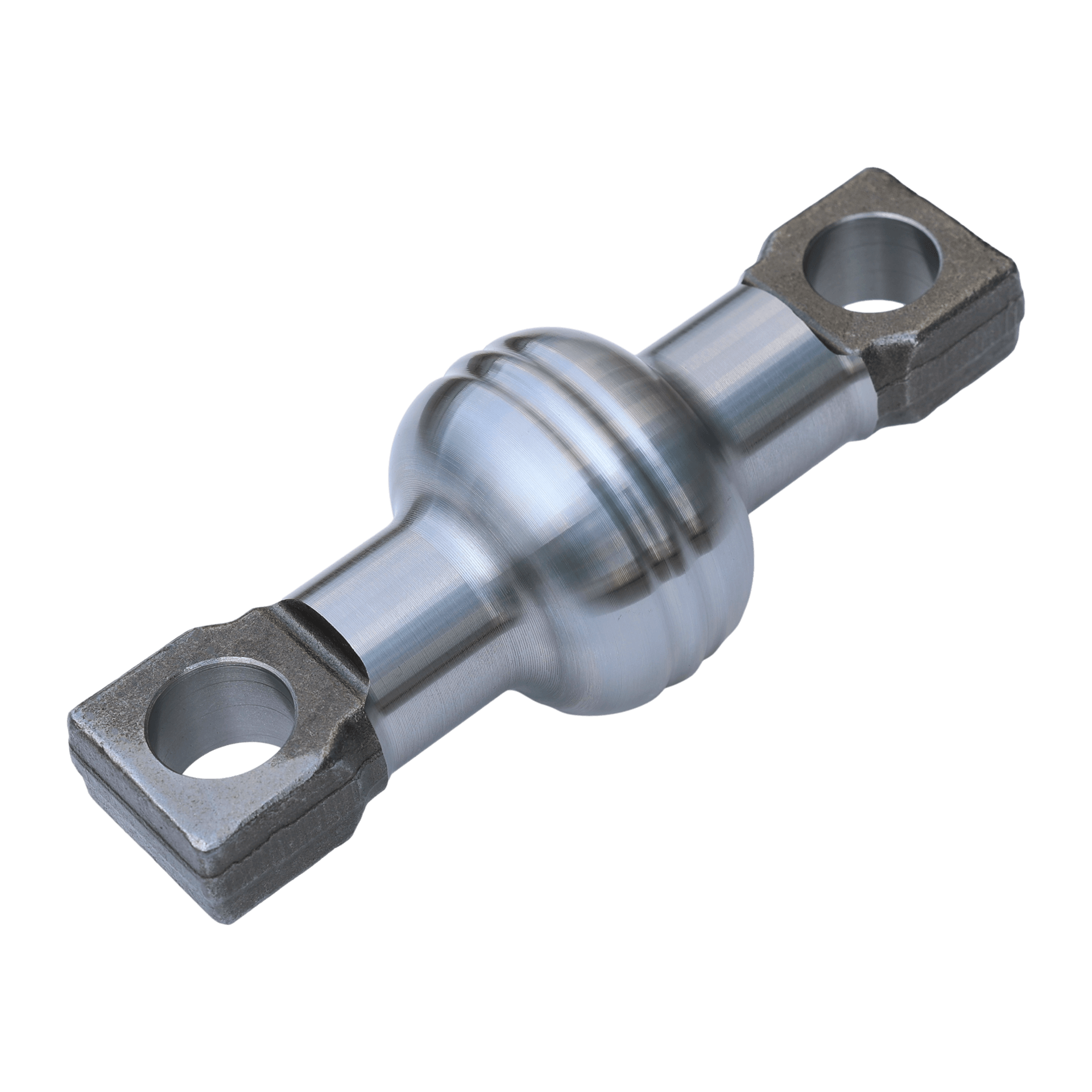

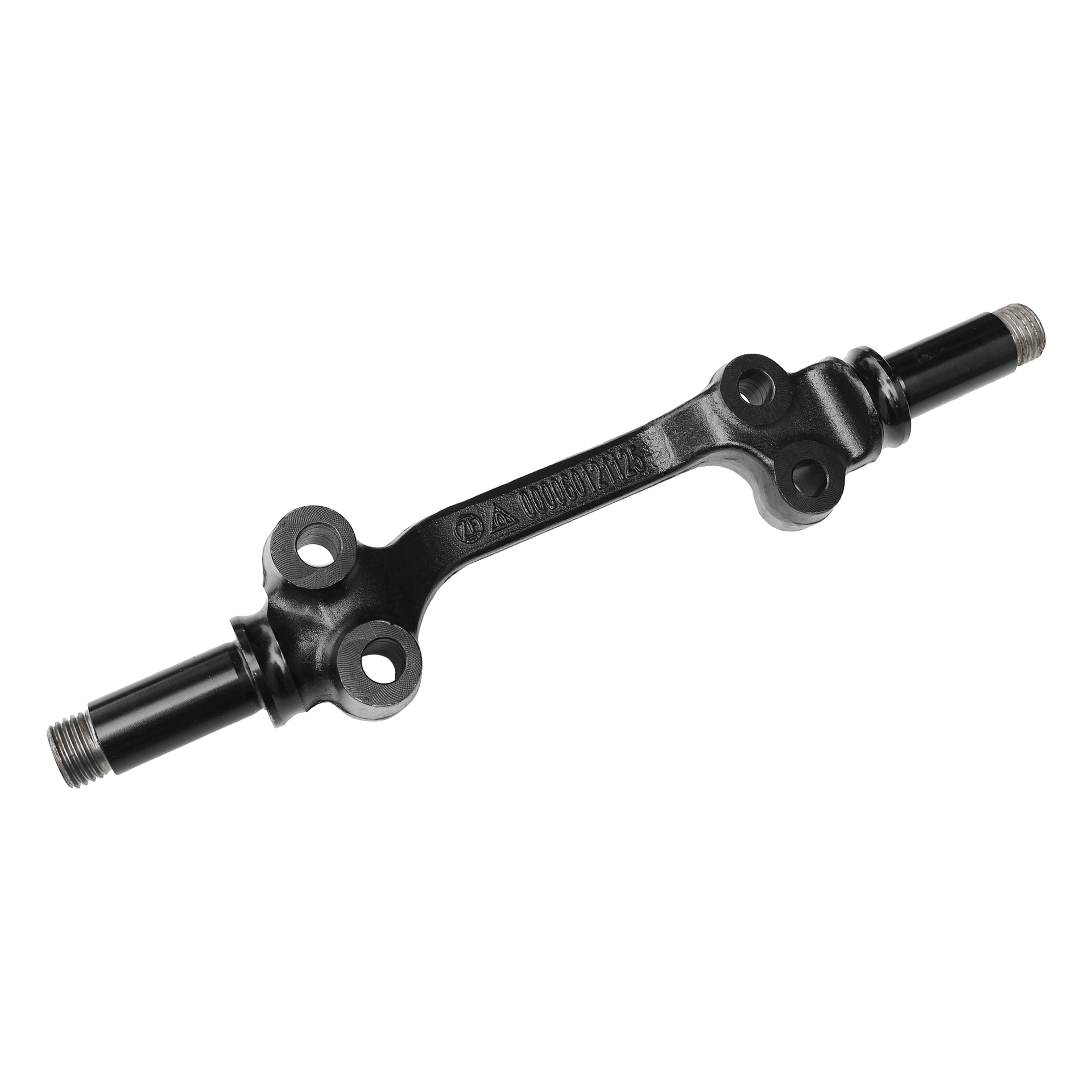

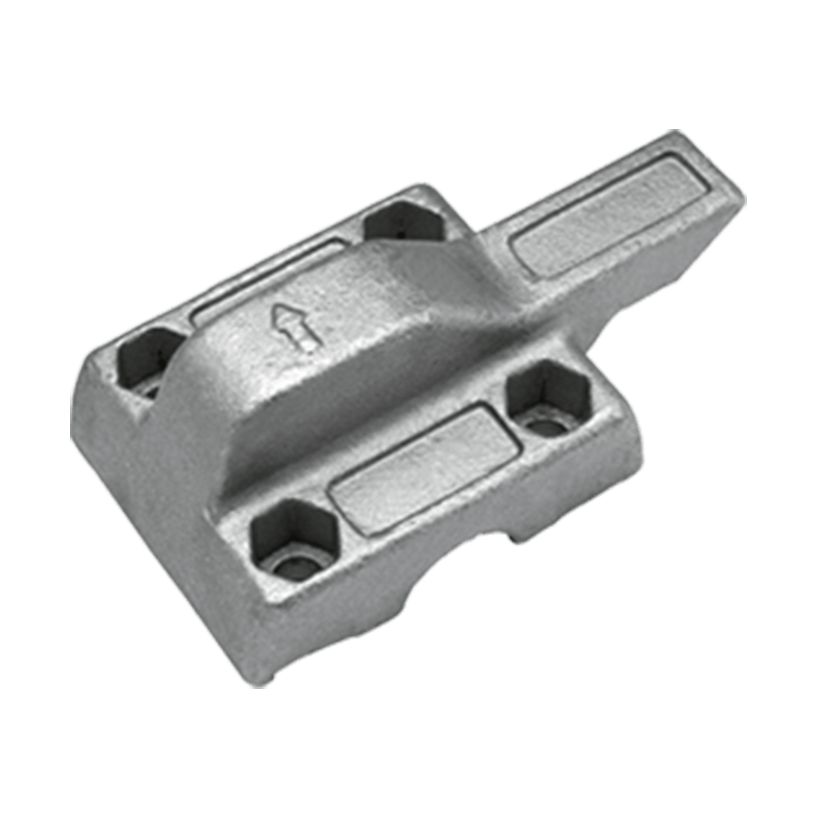

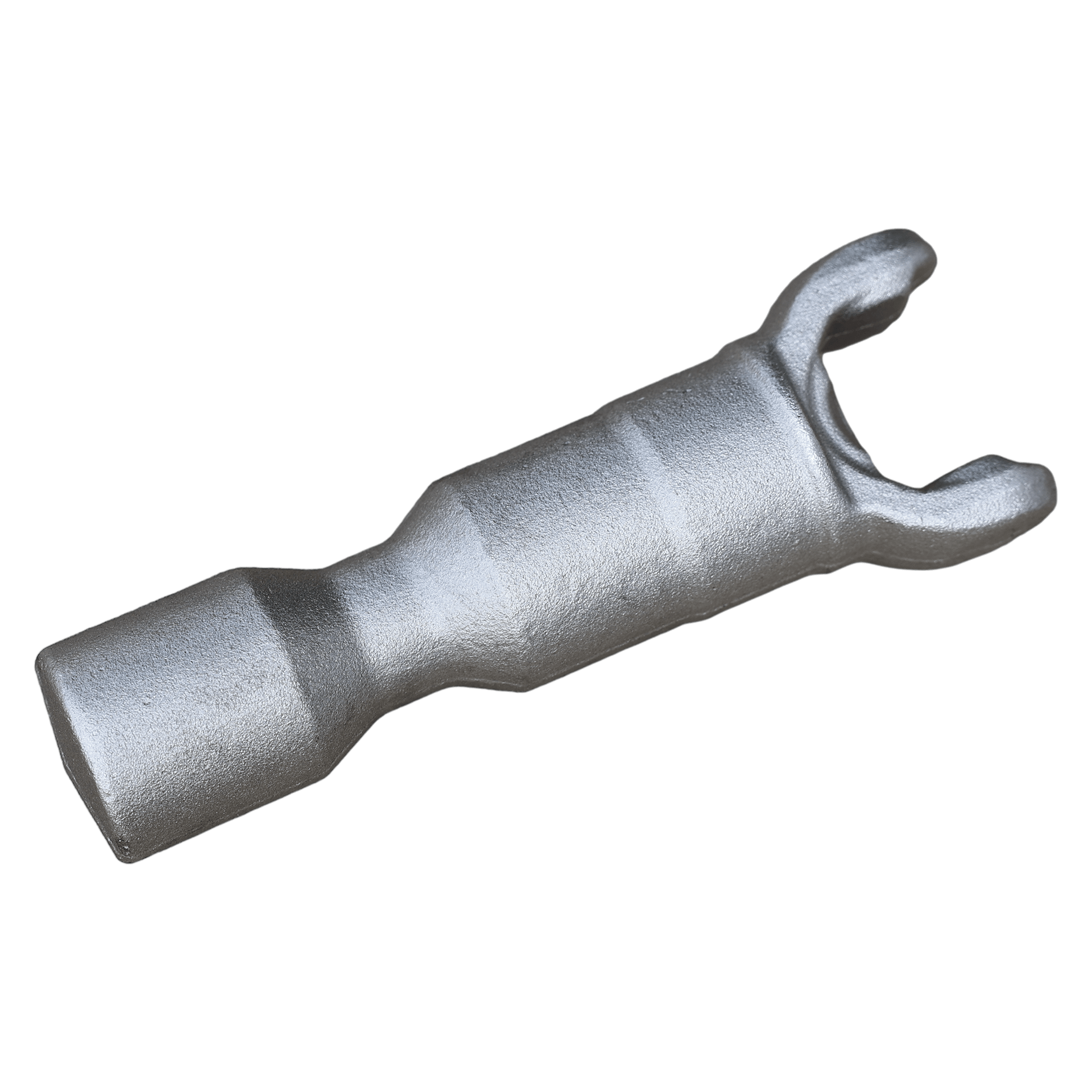

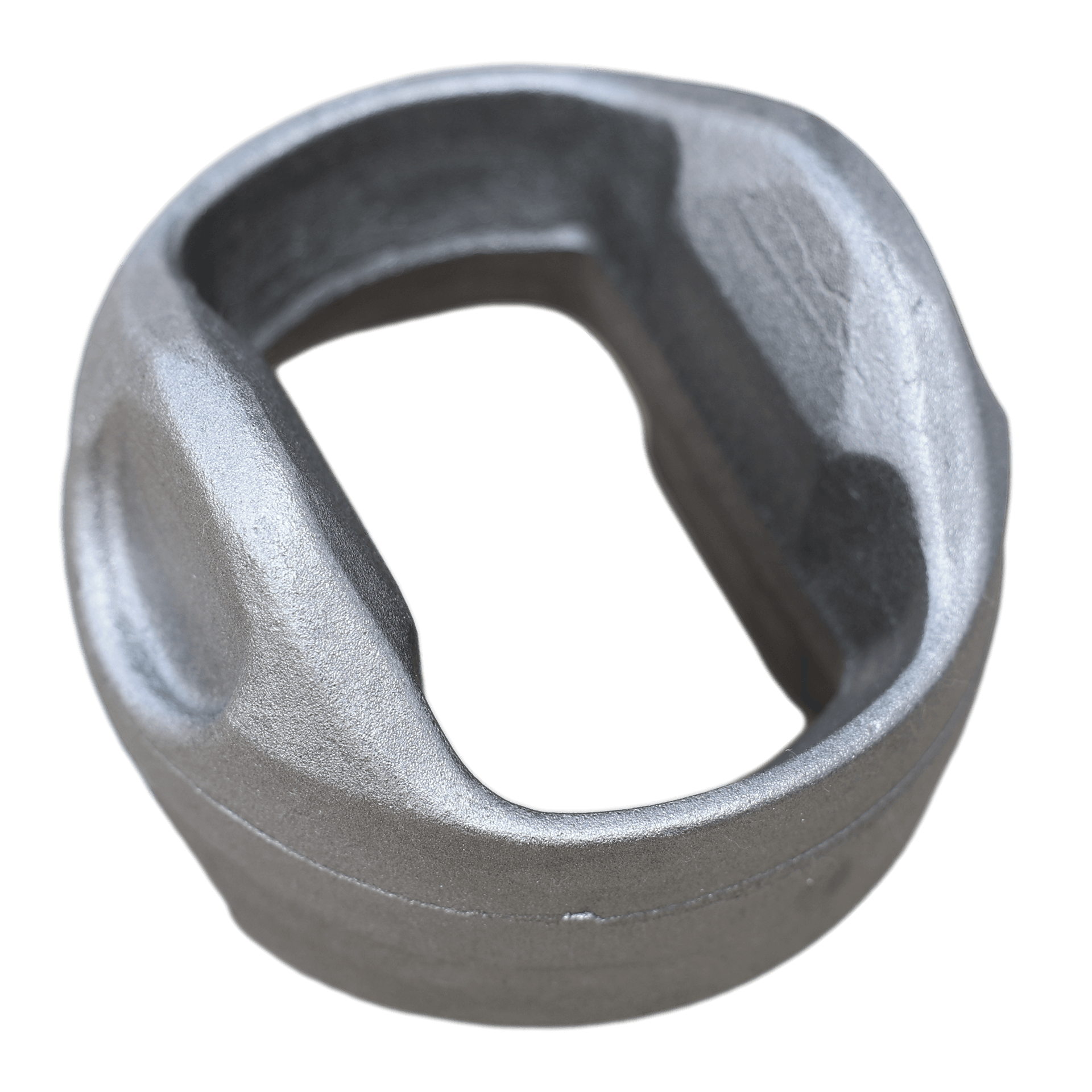

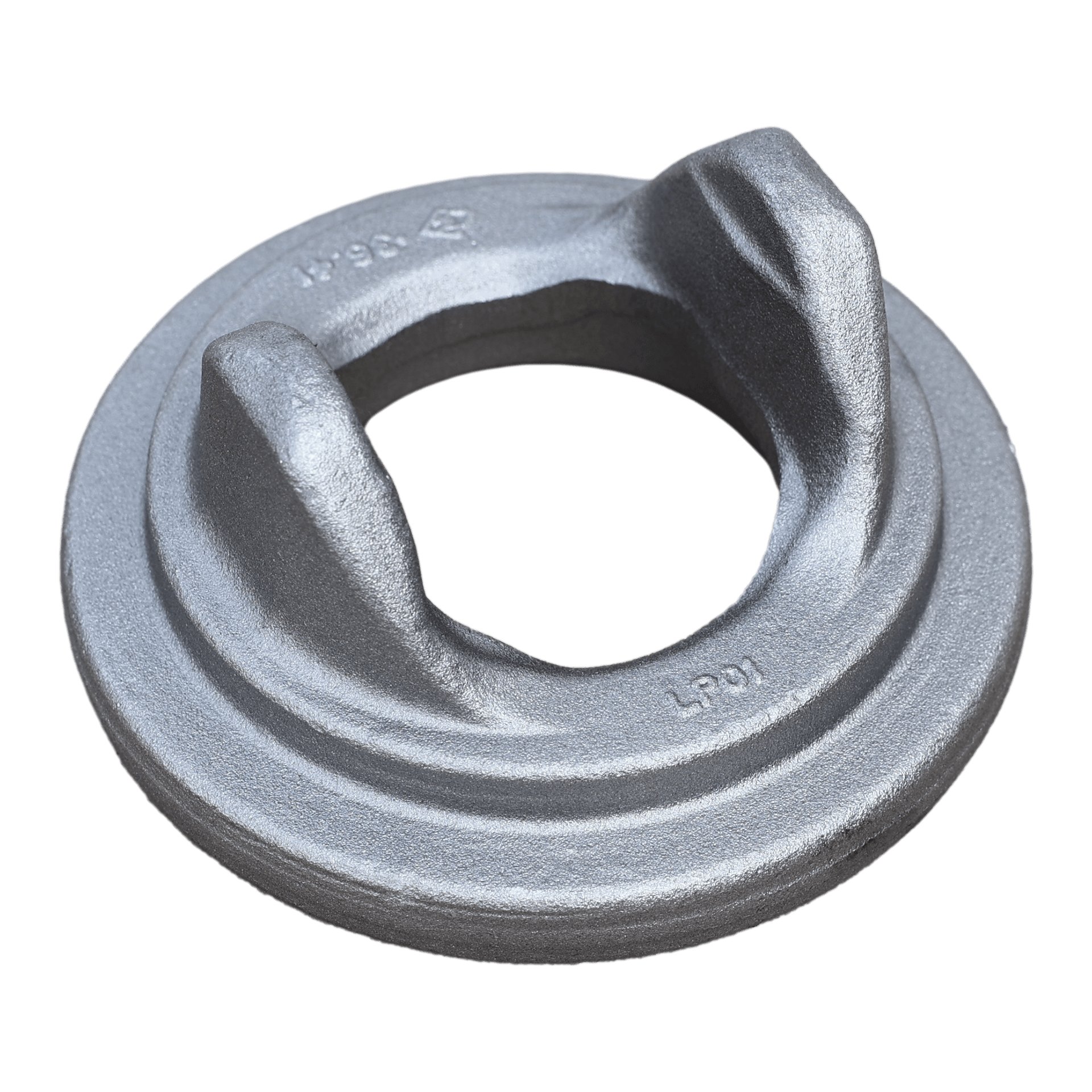

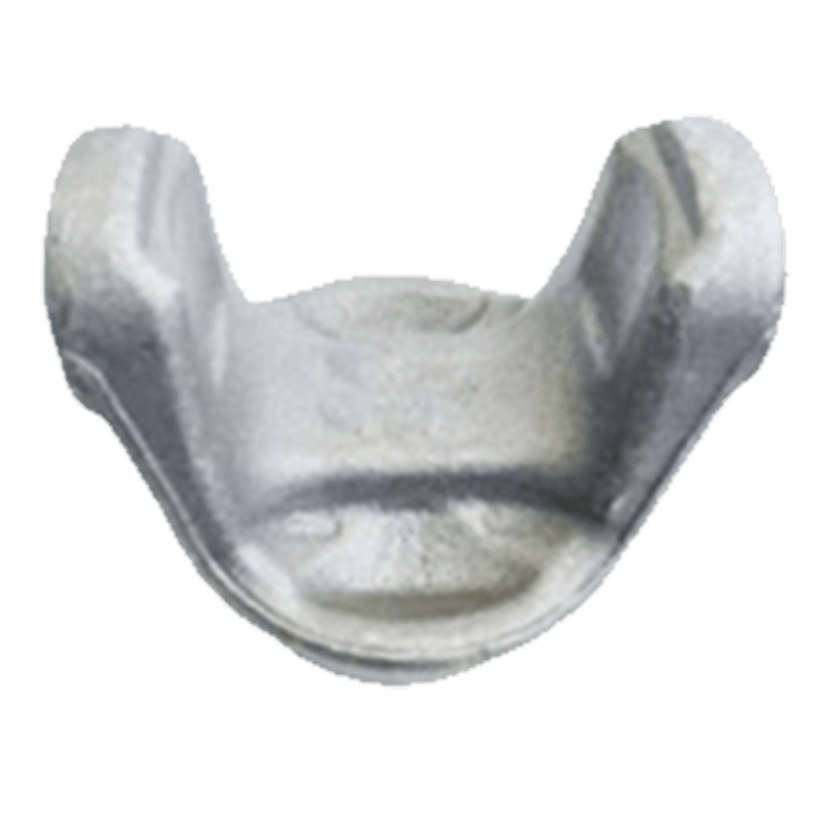

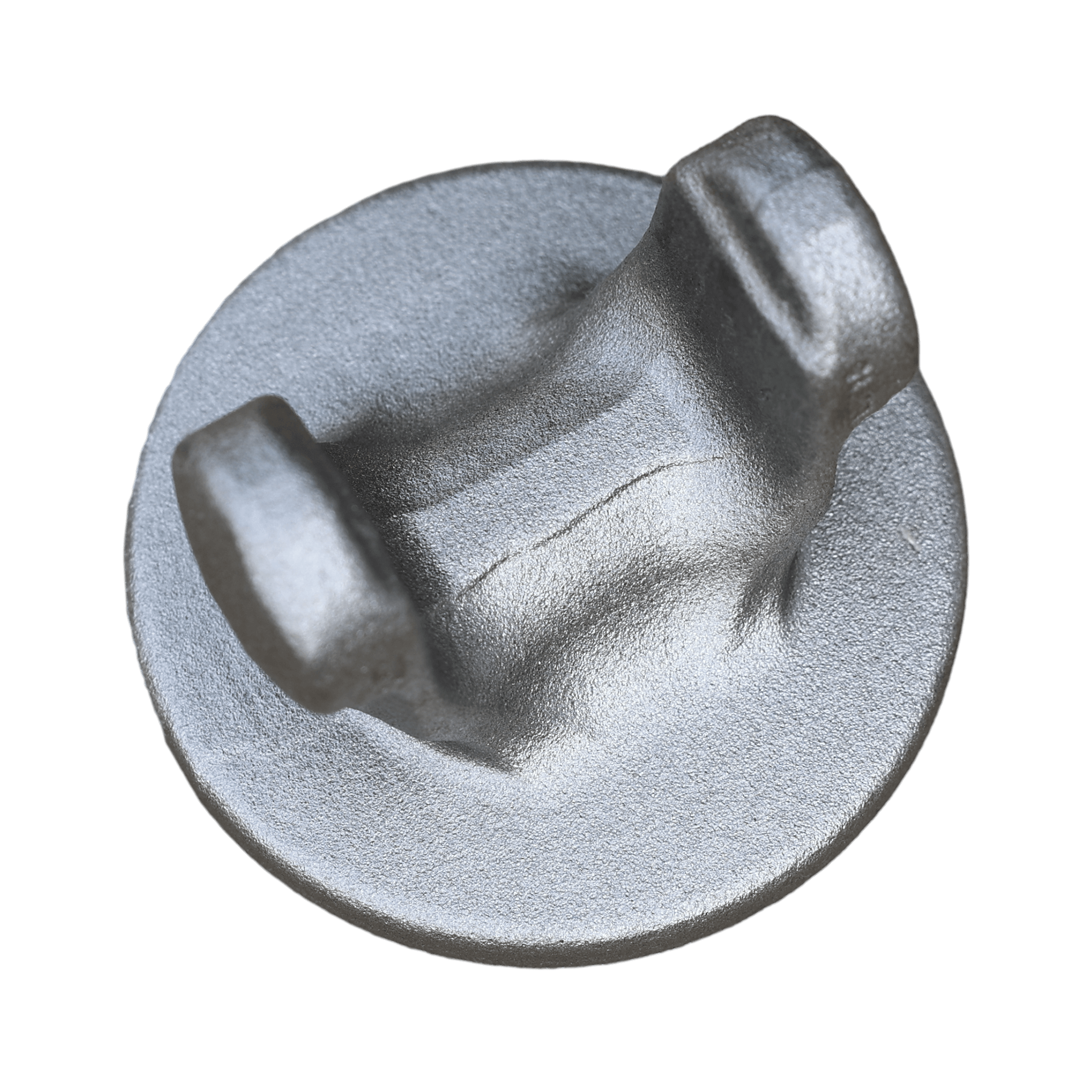

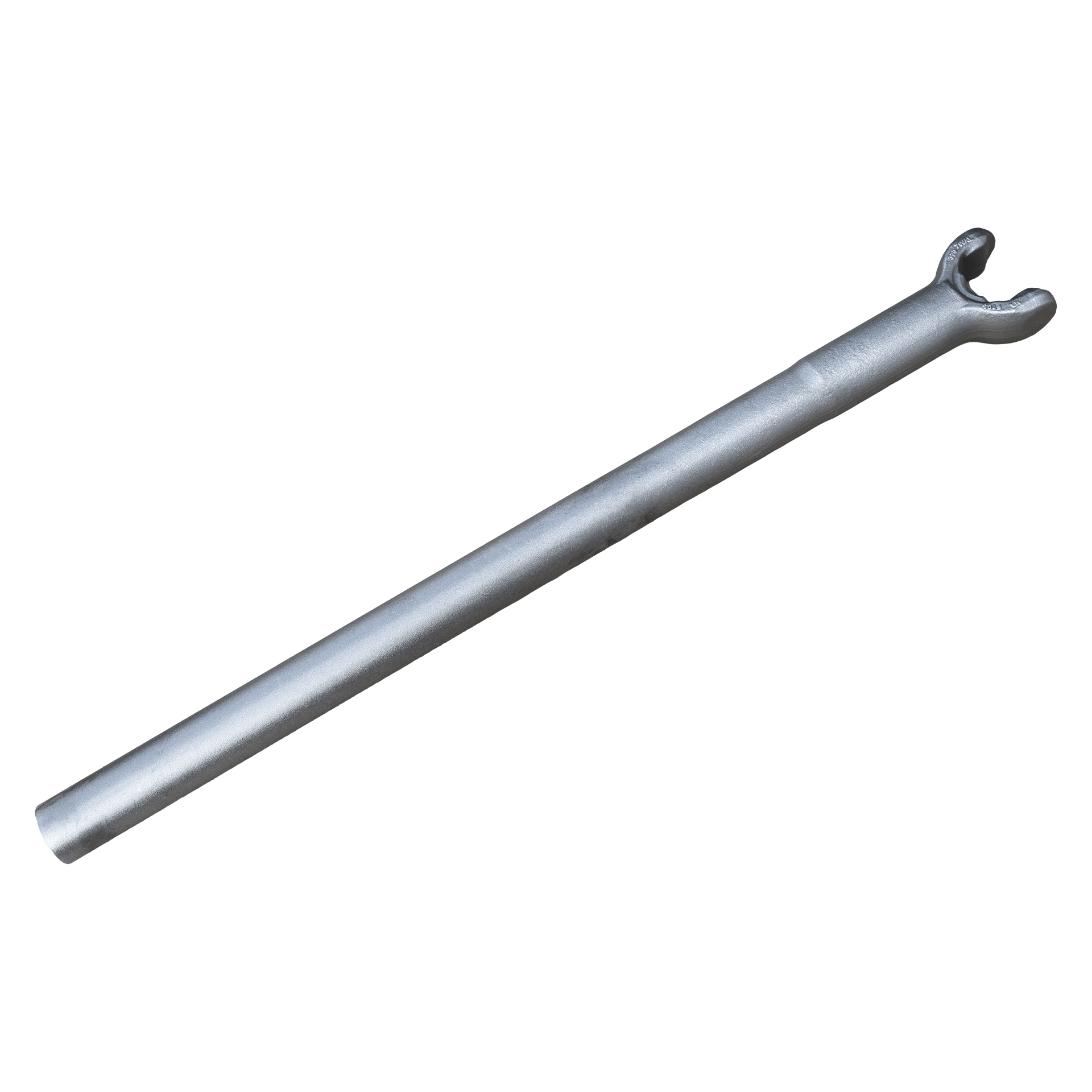

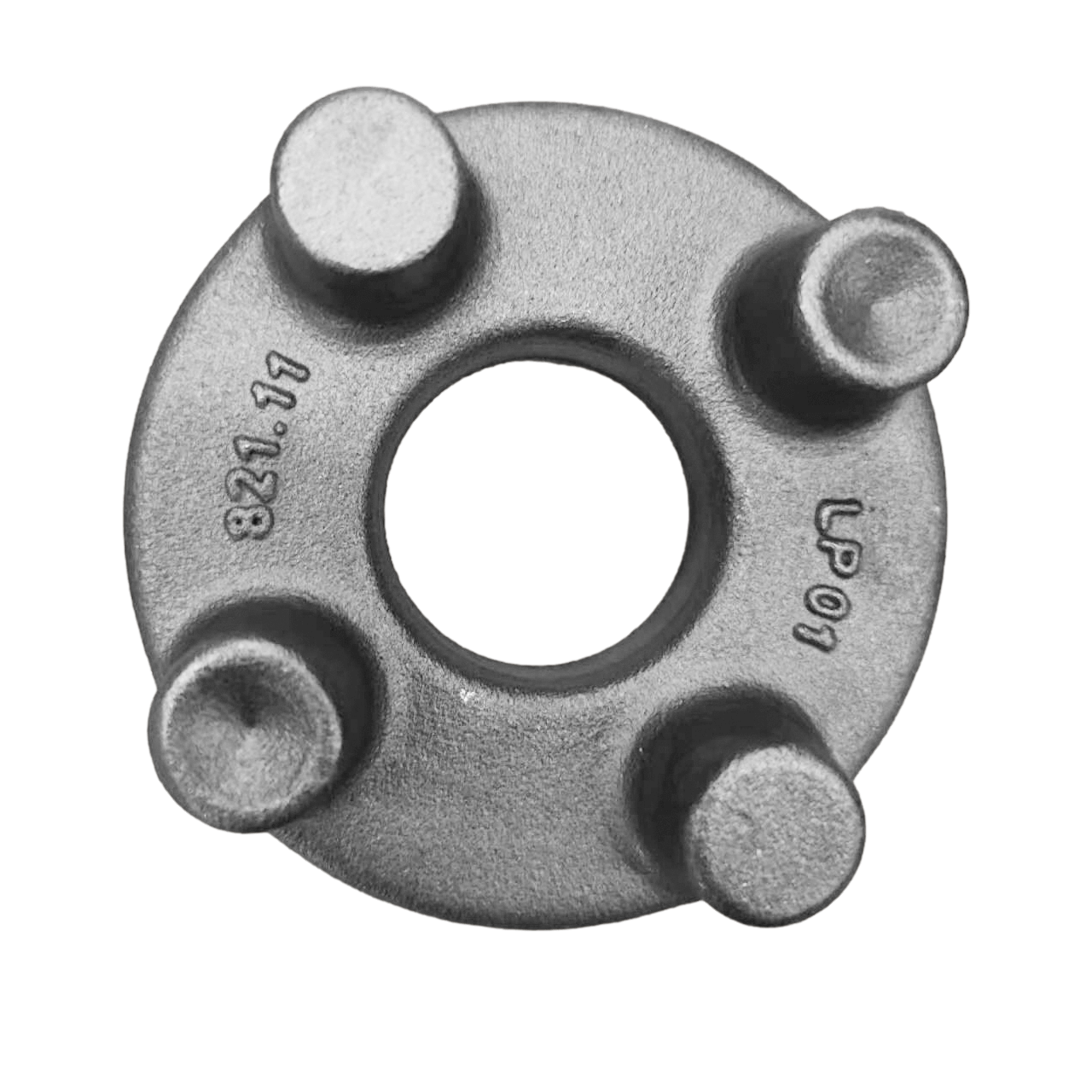

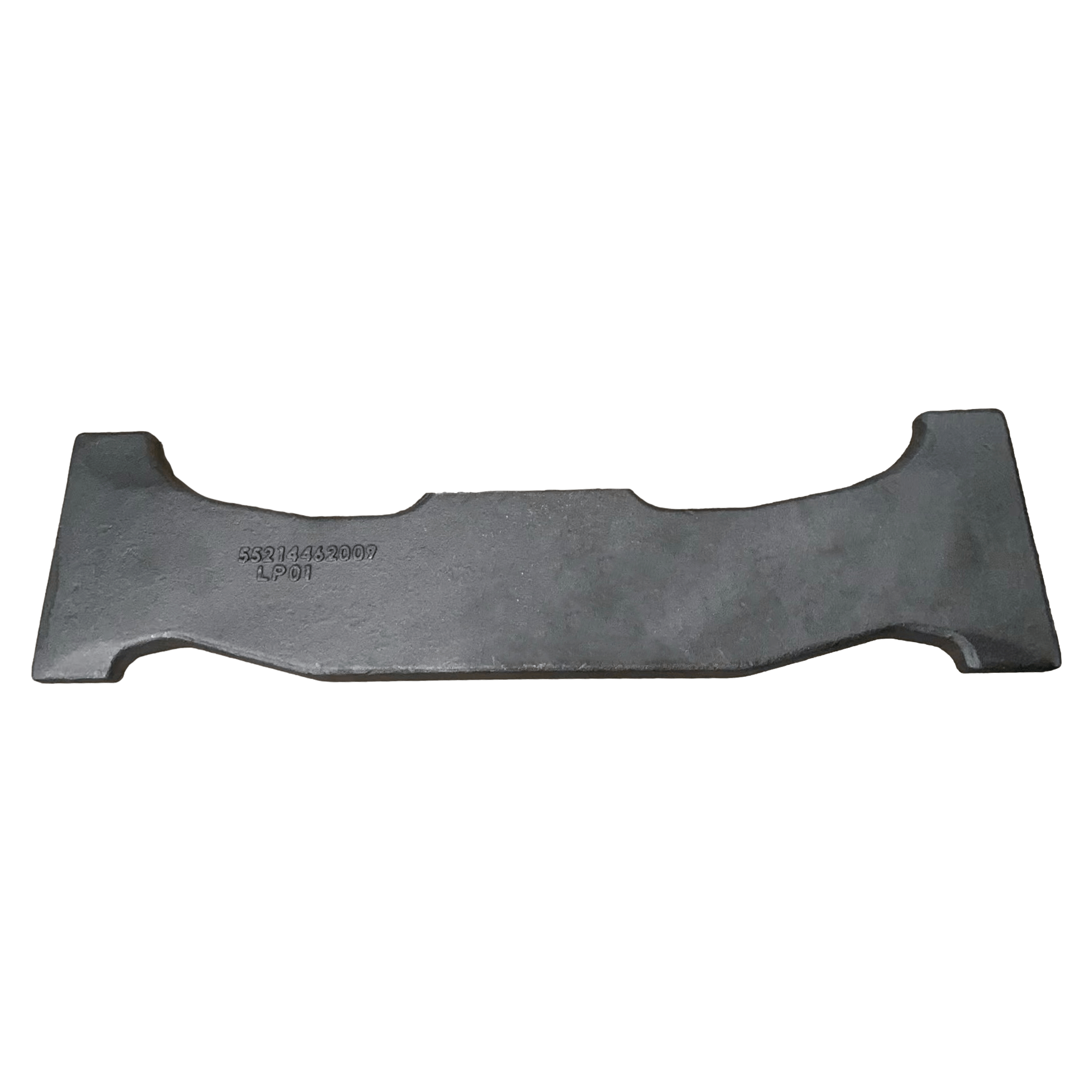

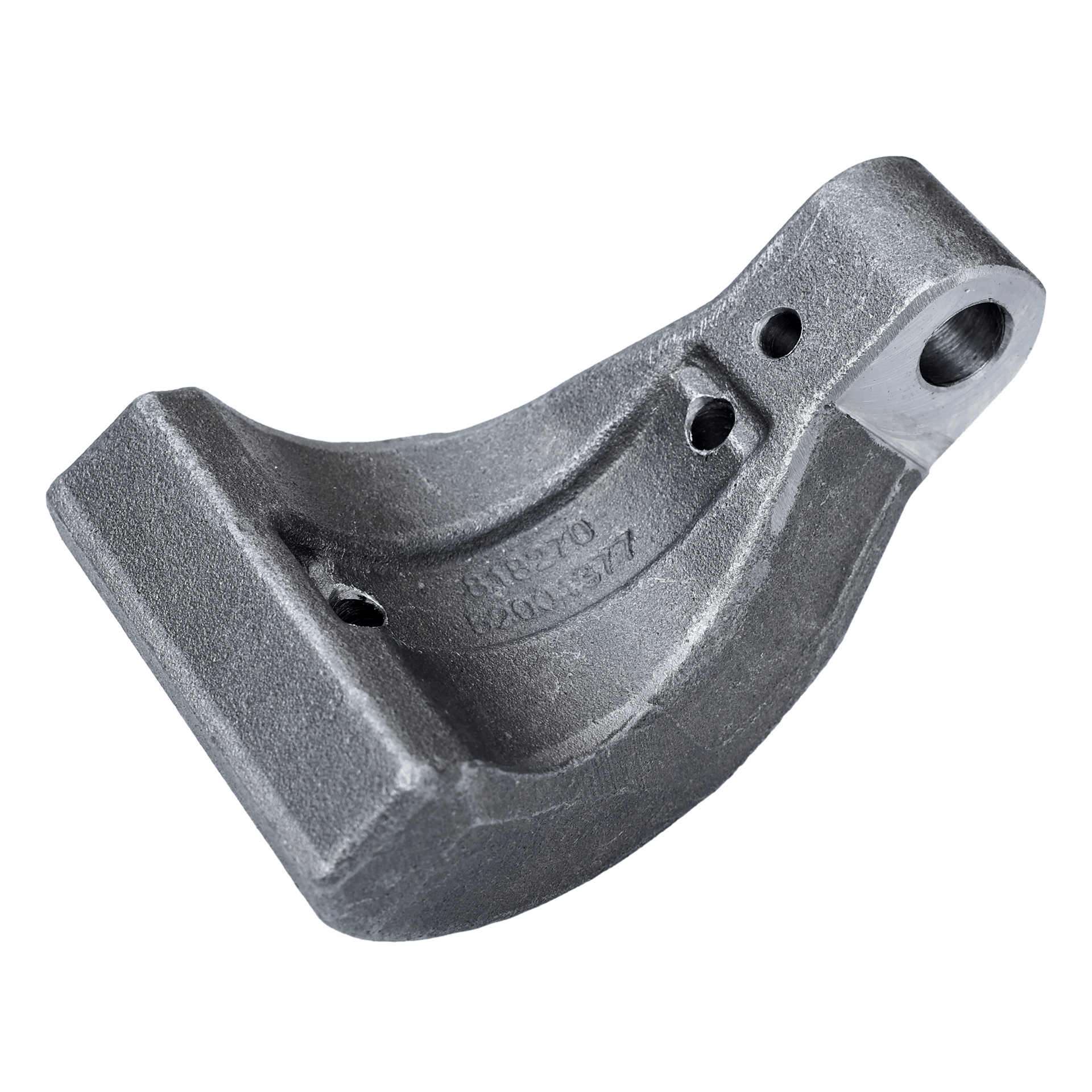

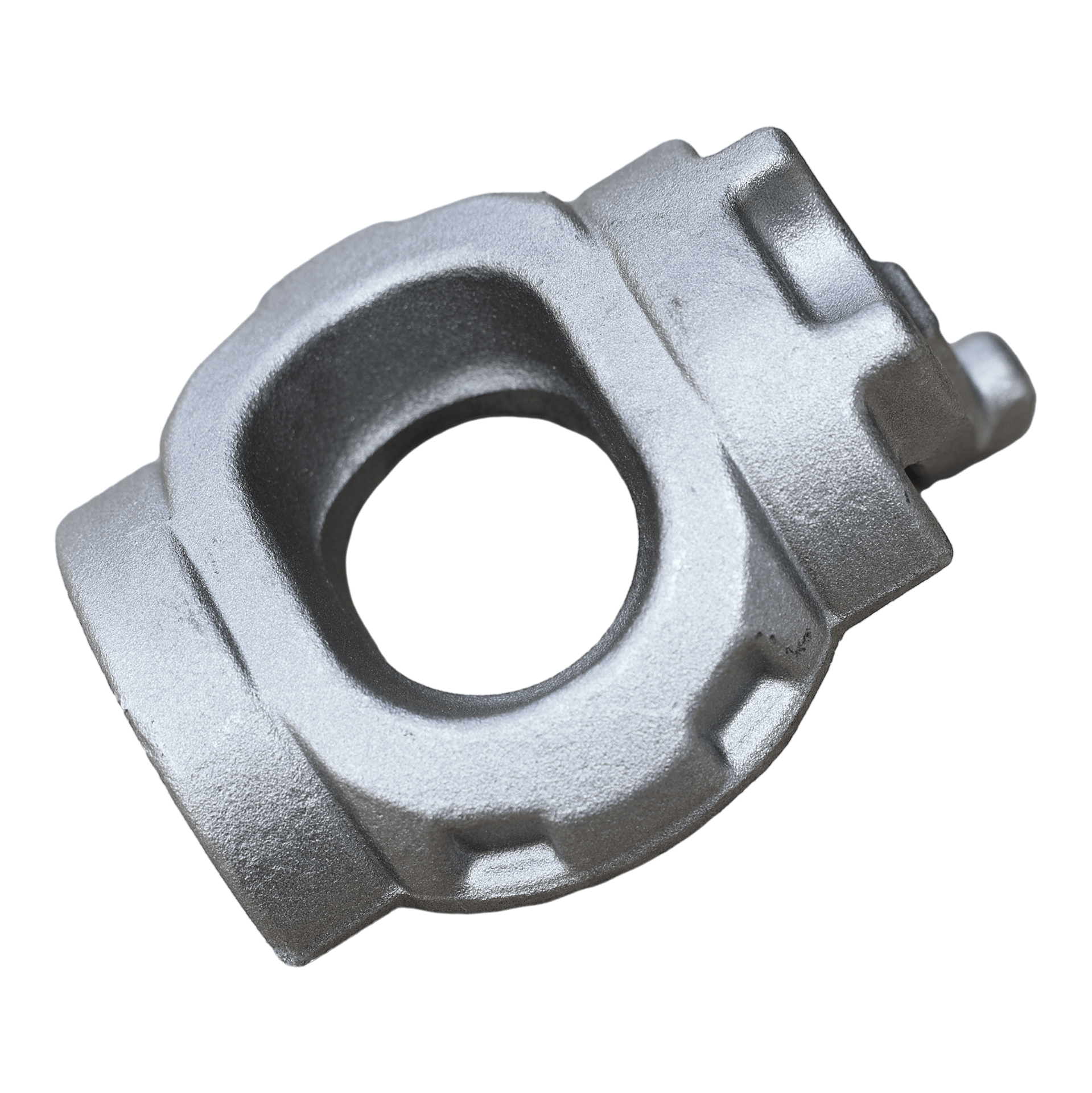

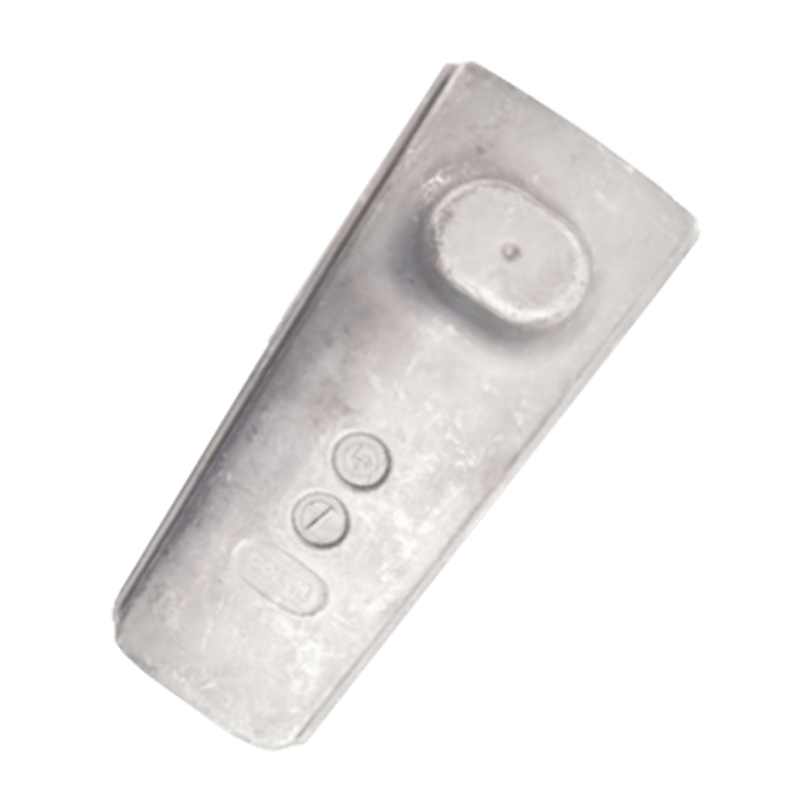

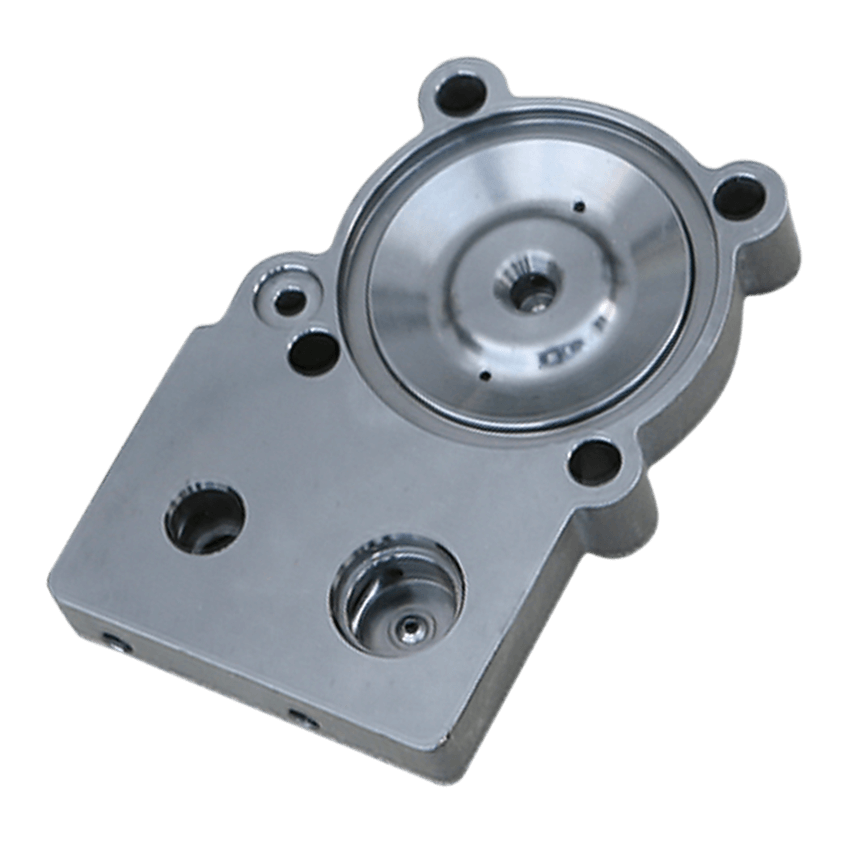

PRODUCT SHOW

Main Products

Equipments

Main Equipment

Forging Equipment

Forging equipment refers to mechanical devices used for forming and separating in forging processes. Forging equipment includes forging hammers, mechanical presses, hydraulic presses, screw presses, and flat forging machines used for forming, as well as auxiliary equipment such as forging operators, uncoiling machines, straightening machines, shearing machines, etc.

Tooling Making/Molding Equipment

Mold processing equipment includes multiple types, which work together to complete the entire process from mold design to finished products. Mold processing equipment mainly includes the following categories: First, CNC machine tools. CNC machine tools are the core equipment in mold processing, including CNC milling machines, CNC lathes, CNC EDM machine tools, etc.

Heat Treatment Equipment

Heat treatment equipment is a device used to implement heat treatment processes, aimed at controlling the properties of metal materials by changing their surface or internal structure. Heat treatment equipment includes various types, such as heat treatment furnaces, heating devices, surface modification devices, surface oxidation devices, quenching and cooling devices, etc

Machine Equipment

Machining is the process of manufacturing components and products that meet the requirements by cutting, drilling, grinding, and other processes on raw materials using machine equipment. In the machining process, various types of mechanical equipment are required to complete different machining operations.

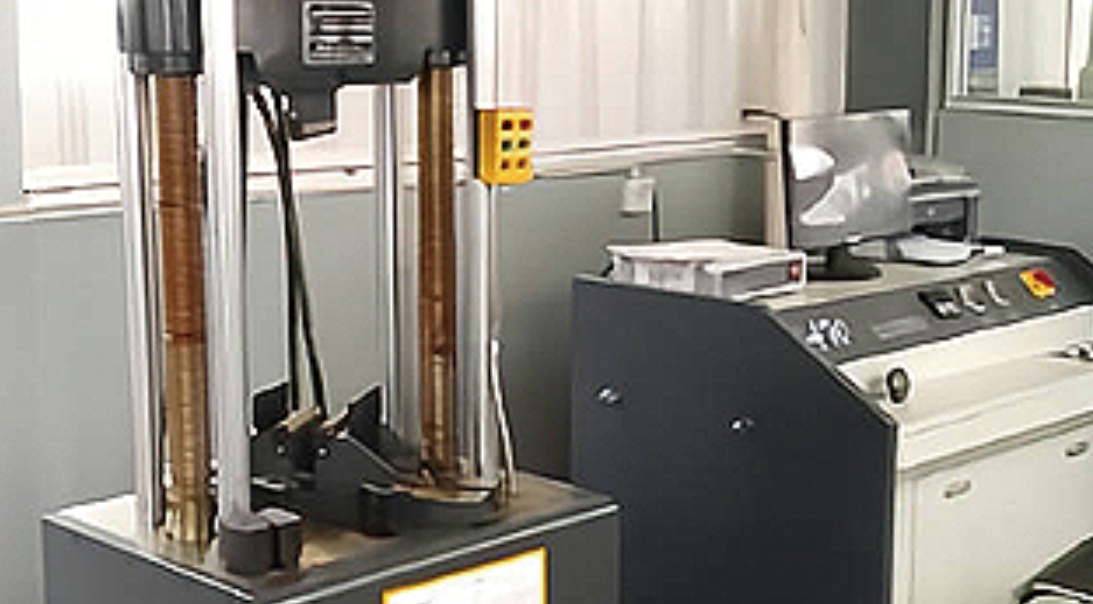

Inspection/Testing Equipment

Testing equipment refers to devices used in production, scientific research, and other fields for detecting, measuring, and analyzing various parameters and performance. These devices are widely used in various fields such as industrial production, scientific research, and medical health to ensure product quality, environmental safety, and human health.